I was super excited when this class appeared on the 18 Reasons calender~Homemade Cheddar! How cool is that? Cheese is my favorite food.

The class was taught by Louella Hill, The Milkmaid.

So here's what went down:

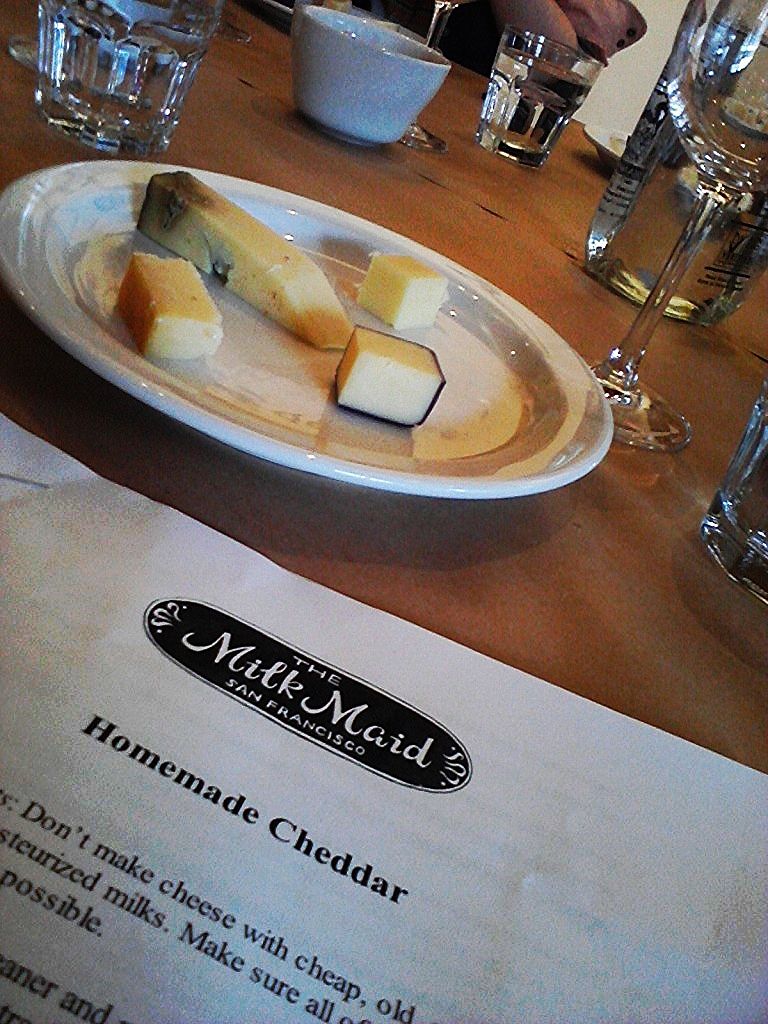

Getting ready to make cheddar. First we taste~on the plate at 1:00: Fresh Tillamook cheddar, moist and buttery. Mild. Supermarket shrink wrap. @4:00 Cabot Vintage Cheddar-one of my favorites-still fairly moist and buttery, much tangier than the Tillamook. This has been my go-to everyday cheese for the last year. It's a wax coated cheese. Aged ??? @8:00 Cabot Clothbound Cheddar or what is also called bandage wrapped. The flavor is so much more intense than the previous cheeses. Finally @10:00 Keen's Cheddar from England. It's got a big moldy veins. YUM! Drier and even more intense than the Cabot. Saltier, savorier. good stuff.

Raw milk is gently heated to 91 degrees, cultured buttermilk is added, then rennet (the enzyme that creates curdling). About 30 minutes later you have a pot of what basically feels like custard. With a knife you start slicing through the custard in straight line cuts a half inch apart, turn the pot 45 degrees and cut again forming 1/2 " grid cuts. Moisture is releasing and here comes the whey.

Then with a flat straining ladle, start making horizontal cuts and gently stir.

After 30 minutes of stirring the curds, and maintaining the 91 degree temperature, break up smaller and smaller until you end up with something that looks like loose cottage cheese, temp increases to 105 and stirred for another 15 minutes.

Drain and place the curd, which has clumped into a large mass, in a large bowl and break apart and crumble with your fingers. The thing that surprised me the most was the sweetness of the whey. It made me very sad to see it go down the sink. Traditional ricotta is made from cooked whey.

The curd is still releasing moisture. The curds are scooped up and put in the straining basket and then pressed.

We got cheese...well sorta. This round was only lightly pressed to form it into a wheel that we could all take a picture of. What really happens is that the curd is left in the press overnight with 50 pounds of weight on it to extract all of the moisture. Aged cheddar has to be super dry so as not to mildew while it ages.

Once the wheel has been compressed overnight, it's left to sit out for a day or two in order to dry out and form a skin.

At this point in the class we were each given a small wheel which had been previously made, so that we could commence with the wrapping. We cut up strips and circles of clean white cotton, dipped the "bandages" in bacon fat and wrapped the cheese to protect the cheese while it ages.

We were given little plastic mesh mats and instructed to age our cheese in a zip lock bag in the vegetable drawer of the refrigerator or better yet- in our wine refrigerator <snort>. The cheese needs to be turned every day.

This is called affinage, the care and aging of cheese.Stay tuned.

No comments:

Post a Comment